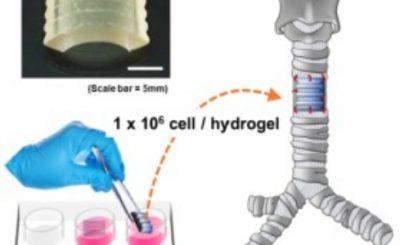

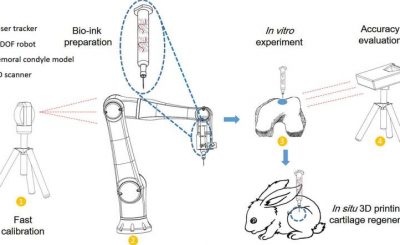

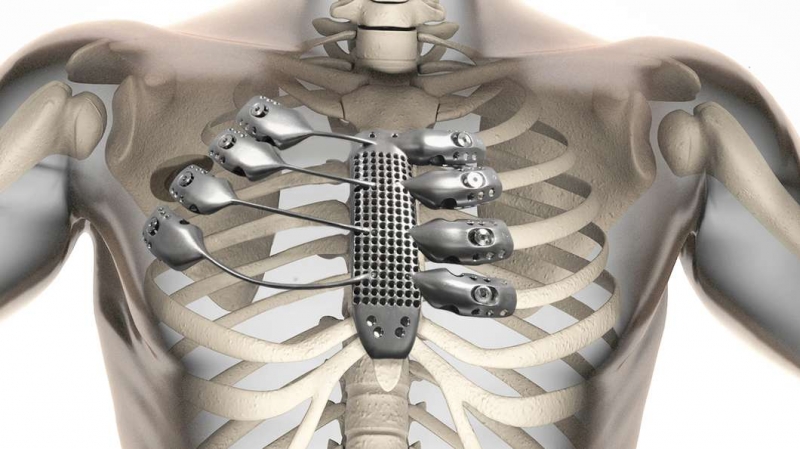

3DPI’s newest writer, Davide Sher, recently  “The soft tissue prostheses project we undertook with the University of Sheffield is a two part process using off the shelf technology. We create a prostheses scaffold using a standard colour 3D printer, which we then infiltrate with medical grade silicone. Naturally, as Industrial Designers, we wanted to perfect a system to use as few stages as possible, so as to make it as commercially viable as possible, so we asked ourselves the question ‘could we print in silicone direct?’; as no such system was available we started on the journey to create the method for Picsima 3D Printing.”

“The soft tissue prostheses project we undertook with the University of Sheffield is a two part process using off the shelf technology. We create a prostheses scaffold using a standard colour 3D printer, which we then infiltrate with medical grade silicone. Naturally, as Industrial Designers, we wanted to perfect a system to use as few stages as possible, so as to make it as commercially viable as possible, so we asked ourselves the question ‘could we print in silicone direct?’; as no such system was available we started on the journey to create the method for Picsima 3D Printing.”

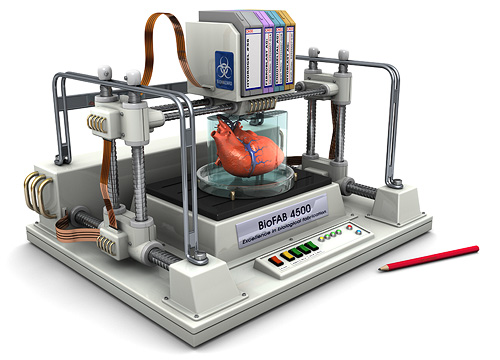

The Picsima process has already proven its ability to create full-colour, fully functional prototypes with a wide range of materials, a shore hardness of less than 25 (which is relatively soft if I understand this Wiki page correctly), and the ability to withstand temperatures as low as 60˚ below zero and greater than 200˚.

Now, the company has to decide how to share this technology with others, while still maintaining a profit, with co-founder and majority shareholder, Steve Roberts, saying, “Tom and I set the company up to invest our resources to develop our own IP for either license or sale. This is still our preferred model, however the idea of becoming the next big manufacturer in 3D Printing also has its appeal.” Roberts summed up the company’s options simply, “Do we sell it, licence it or make it?”

It will be interesting to see which route they take ….