A group of researchers in Hallym University have proposed a new 3D printed cartilage – a digital light processing 3D printed silk fibroin hydrogel for cartilage tissue engineering- with the goal of applying to the fields of tissue engineering needing mechanical properties like cartilage regeneration .

In the past few years, the interests of Digital Light Processing (DLP) using as a 3D bio printing technology for the creation of more complex tissue and organ structure has been increased. DLP 3D bioprinter is based on a local photo polymerization process with cross-section of the product to cure the liquid photo-curable resin layer by layer induced by UV projection. DLP 3D bioprinter provide speedy printing time at 1 mm3 per every second with high resolution about 1 μm. due to short printing time without nozzle system and printing in the aqueous process, higher cell viability could be served compare to other 3D printers like inkjet, extrusion and laser assisted type printer.

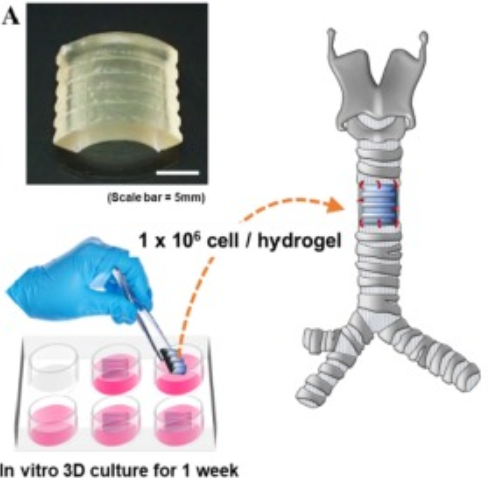

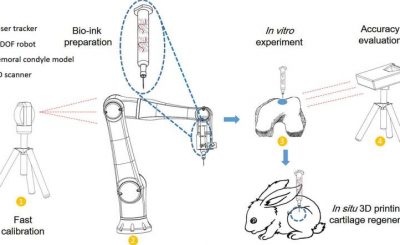

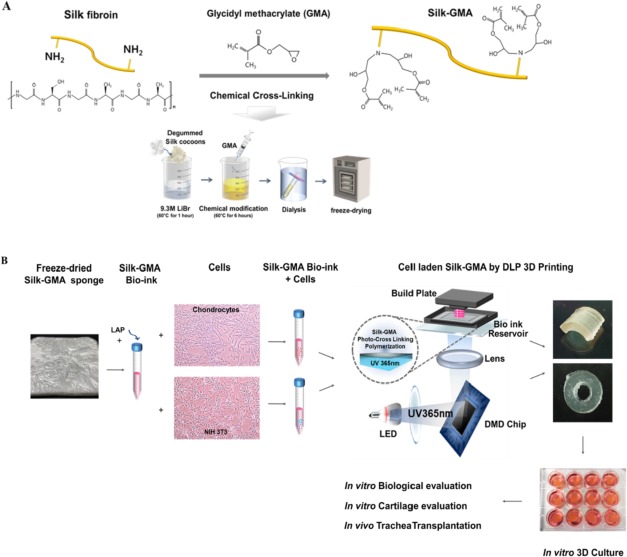

In this study, silk fibroin hydrogel was seleted to form 3D crosslinked hydrated fibers in the DLP 3D bioprinting. Silk fibroin (SF) has its unique advantages, and which has been used for a various biomedical and biotechnological applications due to biocompatibility, biodegradability, high tensile strength, and excellent biological characteristics such as proliferation and adherence of various cells, and low inflammation. Therefore, 3D printed silk fibroin scaffold is a better choice compared with 3D printed hydrogel as a scaffold. The researchers demonstrated that fabricated human and rabbit derived chondrocyte laden SF hydrogel modified with GMA preparing by DLP 3D printing and evaluated its applicability as an artificial trachea with in vivo transplantation for the first trial. Moreover, their study confirmed cytocompatibility, mechanical properties and biodegradability of the hydrogel, glycosaminoglycan (GAG) production, histological chondrogenic expression and new cartilage formation in vitro and in vivo transplantation.

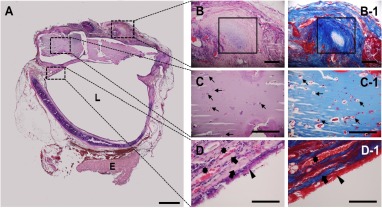

They also conducted the in vitro experiments. With endoscopically monitoring for 6 weeks after transplantation to partially trachea defected rabbit model. Briefly, 1) capability of chondrocytes-laden Silk-GMA hydrogel for chondrogenesis under in vitro condition, 2) mechanical properties of Silk-GMA with or without chondrocytes compare to native tissues and another source, such as Gel-GMA, 3) transplanted cultured Silk-GMA hydrogel with chondrocytes into the trachea defect rabbit model, and 4) evaluation of possibilities under in vivo condition for differentiation to cartilage tissue of chondrocytes-laden Silk-GMA with histological analysis.

Reference: Hong, Heesun, et al. “Digital light processing 3D printed silk fibroin hydrogel for cartilage tissue engineering.” Biomaterials 232 (2020): 119679.

Source: https://www.sciencedirect.com/science/article/pii/S0142961219307781