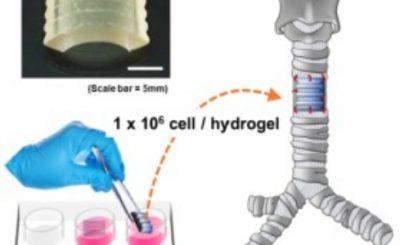

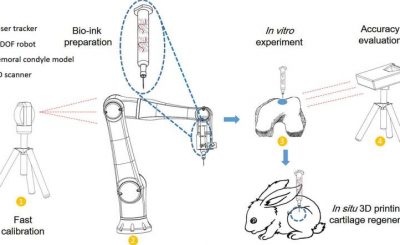

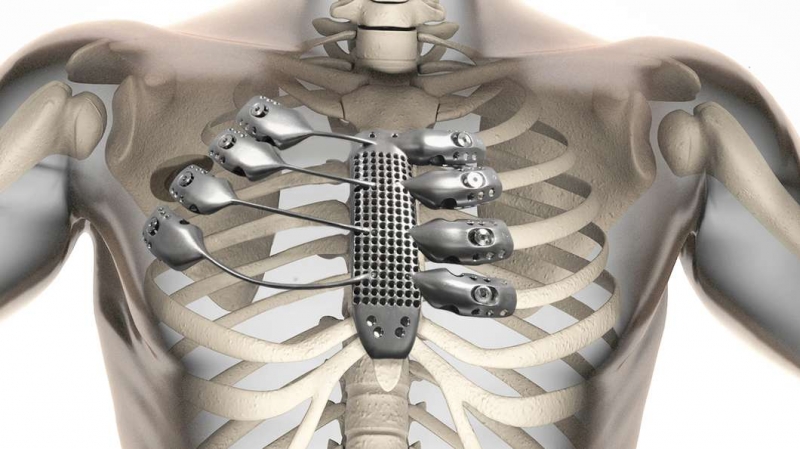

A team led by a mechatronics engineer has found a way to push the boundaries of 3D printing and replace bones and joints with 3D printed versions that actually graft to the existing bone.

Mihaela Vlasea graduated from the University of Waterloo and stayed on to change the world, but she is not the only one working on this concept.

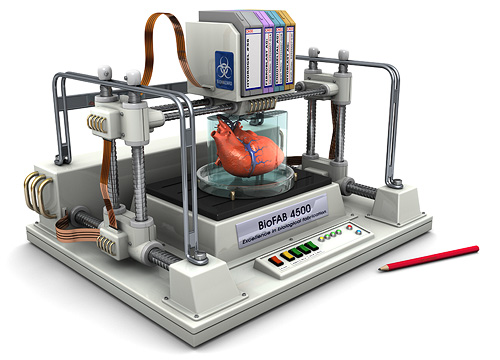

“We’re getting some fantastic physical properties out of additive manufacturing,” says Ehsan Toyserkani, who runs Waterloo’s Multi-Scale Additive Manufacturing Laboratory. “The mechanical strength we are getting is much better — in some cases as much as 25 per cent improvement — over conventional manufacturing.”

Even the artists get a go

Different departments have also embraced this move into 3D printing. Architecture students can see their designs come to life, the design school makes full use of the Fortus 360mc printer when the medical team isn’t in full flow and the university has actively encouraged 3D printing to take a central role.

The University of Waterloo has even created a 3D printing centre of excellence, based on this groundbreaking medical work, which it hopes will make it a pillar of the Canadian tech community.

Additive printing is shrewd business for educational institutions, big business and the world at large. If they commit now, smaller schools can ride this wave to the top.