This week, I had the pleasure of speaking with Bill and Brian Layman, the father and son team behind  While perfecting their 3D printing process for prosthetics, they’ve also used their Fortus machine to 3D print a variety of non-medical items, “anything from drones to dresses”, under the business name of Nola 3D Printing. Though, due to nondisclosure agreements, they weren’t able to tell me about what they consider to be the most fascinating projects, they let me know that they had a hand in 3D printing a piece of fashion for the 3D PrintShow in New York. The company scanned a model, sending the CAD data to designer Frances Guevara, who then created the files for a bikini, which the company was able to print on their 3D printer.

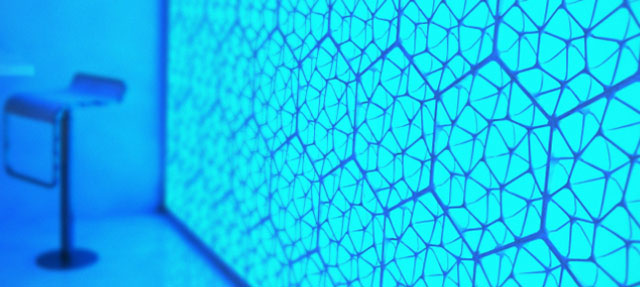

While perfecting their 3D printing process for prosthetics, they’ve also used their Fortus machine to 3D print a variety of non-medical items, “anything from drones to dresses”, under the business name of Nola 3D Printing. Though, due to nondisclosure agreements, they weren’t able to tell me about what they consider to be the most fascinating projects, they let me know that they had a hand in 3D printing a piece of fashion for the 3D PrintShow in New York. The company scanned a model, sending the CAD data to designer Frances Guevara, who then created the files for a bikini, which the company was able to print on their 3D printer.

All in all, though, both Bill and Brian Layman believe that the technology is ripe for their preferred field of prosthetics. Brian explains, “3D printing has pretty much consumed my life. My six-year-old knows words like ‘design’, ‘create’, and ‘CAD’. He knows what an extruder is and what filament is.” But, Brian says that they won’t stop there. If new 3D carbon fiber printing or 3D graphene printing technologies are made available, they will try them. Anything to reduce the weight and increase the comfort and usefulness of their prosthetics.

I left the conversation feeling an optimistic warmth. Their combined 60 years of experience certainly granted them feelings of superiority, yet the men maintained a natural humility about their expertise. Moreover, it was clear from speaking to this father and son that they genuinely cared about the people they worked with. That their patients came first and all else second. To them, 3D printing was a means of helping their patients, and not bringing in business, which is a nice thing to come across in this 3D printing boom.

You can watch a brief video about the family operation below, including some heartwarming stories from patients and footage of Brian and Bill at work: