3D Systems Corporation (3DS) continues to lead the 3D printing industry in many ways. And, in my opinion, one of the primary reasons why is due to President and CEO Avi Reichental’s (mostly correct) strategic market-target decisions. Avi & Co. have a knack for successfully aiming at the hottest marketplace opportunities they regularly foresee for their company.

3D Systems Corporation (3DS) continues to lead the 3D printing industry in many ways. And, in my opinion, one of the primary reasons why is due to President and CEO Avi Reichental’s (mostly correct) strategic market-target decisions. Avi & Co. have a knack for successfully aiming at the hottest marketplace opportunities they regularly foresee for their company.

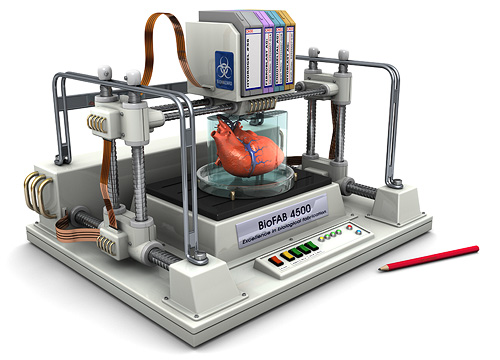

Chief among these is 3DS’ innovative 3DP-solutions applied to the additive-manufacturing susceptible needs of the enormous worldwide Healthcare (HC) industry. Current 3DP-business consensus holds that Healthcare is the fastest growing sector in our industry. IDTechEx — a research house in London — projects that 3DP will be a $7+ billion business in 2025. AND, that $3+billion of that will be comprised of HC-specific products and systems. Furthermore, most of those solutions will stem from Med Sci, BioTech and HC-novel R&D yet to be completed.

Today, the outlines of the future of 3DP in Healthcare can just be discerned. But, the indicators are broad and deep and the foment and ferment among scientists, experts and commentators extensive. Hence, prudent players in both 3DP and HC are beginning to invest in advancing the market-developing discoveries, inventions and innovations that beckon the insiders, the initiated and the in-the-know.

Avi Reichental has perfected a primary technique for garnering the technological and managerial resources to attack perceived marketplaces opportunities. That is to acquire them — lock, stock and barrel. In the last two and a half years 3DS has made over 45 3DP-related acquisitions. Many of these were HC-focused companies or those with HC-applicable solutions (e.g.  According to 3DS, Bespoke Braces for hand and wrist — currently in its pilot phase — is a first-of-its-kind, 3DP-driven medical solution. It enables practitioners to scan, design, and print custom hand and wrist braces. In the Bespoke Braces process, a patient’s arm is scanned and data is transmitted to cloud-based servers. There, a brace design, customized by the patient and clinician, is created to match the shape of the patient’s individual anatomy. Each brace is then 3D printed — using 3DS’ selective laser sintering (SLS) technology — for optimal comfort, flexibility and durability.

According to 3DS, Bespoke Braces for hand and wrist — currently in its pilot phase — is a first-of-its-kind, 3DP-driven medical solution. It enables practitioners to scan, design, and print custom hand and wrist braces. In the Bespoke Braces process, a patient’s arm is scanned and data is transmitted to cloud-based servers. There, a brace design, customized by the patient and clinician, is created to match the shape of the patient’s individual anatomy. Each brace is then 3D printed — using 3DS’ selective laser sintering (SLS) technology — for optimal comfort, flexibility and durability.

The Bespoke Braces system is comprised of an arm scanner, an iPad app, cloud software, a network of 3D printers, and four revolutionary arm brace designs. This service has recently been expanded to include custom scoliosis braces for children and young adults.

According to the Core77 Jury spokesperson, “This product is a strong example of when customization can be leveraged to its true potential, delivering an experience that is integrated, personal and a strong application of the additive manufacturing processes.”

According to the Core77 Jury spokesperson, “This product is a strong example of when customization can be leveraged to its true potential, delivering an experience that is integrated, personal and a strong application of the additive manufacturing processes.”

The robotic exoskeleton — originally announced by 3DS in February 2014 — is the first-ever, 3D-printed, hybrid-robotic exoskeleton “suit.” It was created in collaboration with Ekso Bionics of California. To create a perfect fit for Amanda Boxtel, the paraplegic patient, engineers scanned the contours of Amanda’s thighs, shins and spine. They then created a personalized three-dimensional base to form and shape the required assemblies. Sophisticated mechanical actuators and controls—manufactured and provided by Ekso Bionics—were then integrated with the more fluid components that were 3D-printed from the customized scans to create the first-ever, bespoke robotic suit.