According to the Center for Disease Control, more than half a million people die from heart disease in the United States every year. To diagnose these cardiac conditions and treat them before the worst occurs, doctors are increasingly relying on a process known as cardiac catheterization. In 2013 alone, over 2.7 million cardiac catheterizations were performed in the United States. By inserting a tube, usually via the groin, up into the heart and injecting a dye visible by X-ray, doctors can determine how the heart is performing, the size of its chambers, and if there are any blockages or abnormalities, among other things. Though the process is not a very invasive one, complications can still arise.

The EU-funded

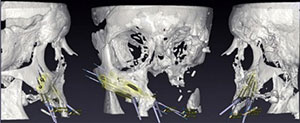

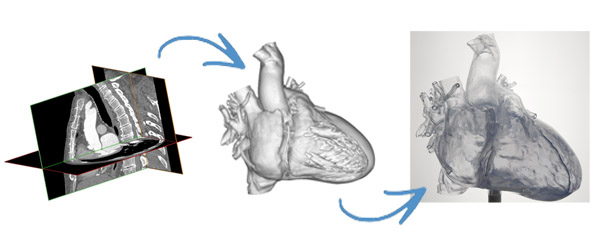

The EU-funded  The model was then 3D printed with Materialise’s HeartPrint® Flex material, which accurately imitates the natural feel of the heart and realistically pulses when attached to a pump for blood flow simulation. Take a look at it on the left. That’s one long, intricate piece of tubing that, inside of the person from which the CT scan was derived, would trace all the way from the inner thigh, up and into the heart itself. And, because the vascular tree print is modular, doctors could potentially 3D print different pathologies that a catheter might encounter on its way up to the heart, such as an aneurysm or tracts of tissues with calcification. As the CASCADE team also hopes to use their smart cath to teach medical students and residents, such 3D printed abnormalities would be ideal for educational purposes.

The model was then 3D printed with Materialise’s HeartPrint® Flex material, which accurately imitates the natural feel of the heart and realistically pulses when attached to a pump for blood flow simulation. Take a look at it on the left. That’s one long, intricate piece of tubing that, inside of the person from which the CT scan was derived, would trace all the way from the inner thigh, up and into the heart itself. And, because the vascular tree print is modular, doctors could potentially 3D print different pathologies that a catheter might encounter on its way up to the heart, such as an aneurysm or tracts of tissues with calcification. As the CASCADE team also hopes to use their smart cath to teach medical students and residents, such 3D printed abnormalities would be ideal for educational purposes.

The CASCADE Project team has already begun working with the 3D printed model and underwent a review from international scientists and a representative from the European Union. After careful consideration and much positive feedback, the project was given the go-ahead to continue their work. CASCADE is still several years away from completion, but Materialise’s vascular model has done a great deal to push it forward. While it may have been possible to create a model of the path from the groin to the heart, there was no way to do so as accurately and realistically without 3D printing technology.