”If 3DP was applicable to larger production volumes in consumer products or automotive manufacturing, it contains the (theoretical) potential to absolutely decouple energy and CO2 emission from economic activity.” — Malte Gebler, Anton J.M. Schoot Uiterkamp, Cindy Visser, 2014, A global sustainability perspective on 3D printing technologies. Available from:

Terms: Total Primary Energy Supply (TPES), Gross Domestic Produce (GPD), Three Dimensional Printing (3DP), Carbon Dioxide (CO2)

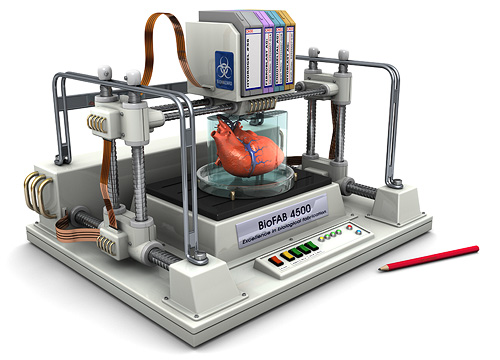

The formulaic approach of the thesis digests a set of fields that pertain to each of the five determined major markets for 3D printing – consumer products, aerospace manufacturing, auto- motive production, medical components and tooling – across four projection scenarios. The variables in those scenarios are a ballpark market potential of low or high, and process intensities of low or high. Process intensities being change in cost, energy and carbon dioxide emissions. Scenario 1 being low market potential and low process intensities. Scenario 4 being high market potential and high process intensities. Scenarios 2 and 3 being a variant of high and low for each.

The paper provides numerical outputs for each of the markets in accordance to each of the scenarios as a basis of projection. The figures are interesting and pertinant, but as said, this article is not a spoiler. Machine and material costs are covered. Averages are taken for each. Also individual 3D printing advanced manufacturing technologies and materials comparitive to the closest extant traditional manufacturing processes are exampled with financial break-even points — such as polymeres for stereolithography compared to injection moulding; aluminium selective laser sintering compared to high-pressure die casting; and so forth.

The results of the formula applied to markets and scenarios and other key variables are then graphed with precision and clarity under the following headings: Annual avoided costs through 3D printing in industry in 2025 in USD$; Relative changes in costs through 3DP per market in industry in 2025 excluding decommissioning; Annual avoided TPES use through 3DP in industry in 2025 in EJ; Relative changes in TPES through 3DP per market in industry in 2025 excluding decommissioning; Relative change in TPES / GDP-intensity through 3DP in industry excluding decommissioning in 2013-2025; and Relative change in CO2/ GDP-intensity through 3DP in industry exluding decommissioning in 2013-2025.

A global sustainability perspective on 3D printing technologies amounts to a must-read paper, in my opinion. Seminal is a term a humble technology journalist such as myself has not the depth of decernment to make regarding an original quantitive research paper of importance such as this. Though, given the original nature of the paper, its relevance to surely one of the most important matters of our age – sustainability – and a breadth of research cited in the paper that is self-evident, perhaps ‘must-read’ is not an overstatement. The conclusions of the paper are quantitive, empirical and lucid — the theses may well go on to become noted by industry, commerce and policy makers:

”The model calculations show that 3DP contains the potential to reduce costs by USD$170–593 billion, the total primary energy supply by 2.54–9.30 EJ and CO2 emissions by 130.5–525.5 Mt by 2025… The energy and CO2 emission intensities of industrial manufacturing are reducible by maximally 5% through 3DP by 2025, as 3DP remains a niche technology. If 3DP was applicable to larger production volumes in consumer products or automotive manufacturing, it contains the (theoretical) potential to absolutely decouple energy and CO2 emission from economic activity.”

Source: Energy Academy Europe / Science Direct

information