Initially, the team would bring pre-made hand components with them, and they’d work on organizing the people and resources necessary to start producing the prosthetics in Haiti. Members of  In order to gain more capital and expertise for their endeavor, the e-NABLE team applied to the

In order to gain more capital and expertise for their endeavor, the e-NABLE team applied to the  The next day brought a presentation in front of the hospital’s top staff of doctors and administrators. As it turns out, they believe the need for full arm and hand prosthesis to be greater than the need for only hands. Luckily this should be no problem for e-NABLE’s flexible maker supply chain.

The next day brought a presentation in front of the hospital’s top staff of doctors and administrators. As it turns out, they believe the need for full arm and hand prosthesis to be greater than the need for only hands. Luckily this should be no problem for e-NABLE’s flexible maker supply chain.

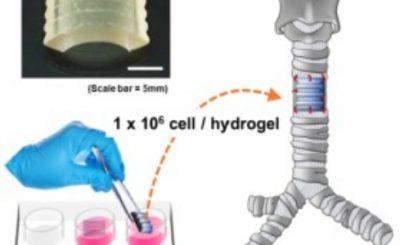

While touring the infant ward of the hospital, Dante learned that the hospital doesn’t have the proper equipment needed to deal with premature infants that have infant respiratory distress syndrome. A Continuous Positive Airway Pressure (CPAP) machine is used when an infant is diagnosed with this syndrome, but a special ventilator mask is needed in order to work with the small patients. 3D printing, then, could help save lives through the creation of a scaled down ventilator mask.

The team left feeling hopeful. Overall, the response they received from patients, doctors, and makers was one of great excitement for the 3D printed prosthesis. Since their trip, the team has been communicating with the doctors they met, and brainstorming ideas for design modifications, procedures for getting prostheses to the patients, and conducting virtual training workshops for hand-assembly. Once the program is established, they hope to use it as a model that can be applied for other countries in need.