Certified prosthetists Tyler Dunham and Tyler Manee have

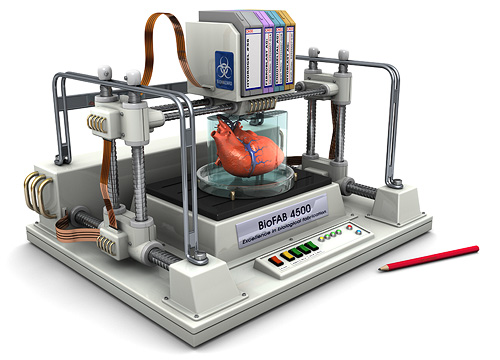

3D printing is gaining steam as a logical and obvious way to lower the cost, decrease material waste, and speed up fabrication time of prosthetic limbs. It has already been used frequently to create hundreds of low-cost replacement hands. Unfortunately, the build envelope of most affordable 3D printers is too small for most of the important, structural parts of a lower limb prosthetic, requiring more expensive, large bed, 3D printer options.

Sadly, most amputees in the country are lower limb amputees, and, as of yet, there are very little options for creating prosthetic replacements for legs available using standard desktop 3D printing. Many of these amputees are returning military veterans, who often need to wait months, even years for customized prosthetic limbs made via traditional methods. The Tylers have spent the last two years researching the feasibility of using 3D printers for prosthetics and think that they have functional designs ready to be printed. All they need is a printer large enough to make their them a physical reality.

Sadly, most amputees in the country are lower limb amputees, and, as of yet, there are very little options for creating prosthetic replacements for legs available using standard desktop 3D printing. Many of these amputees are returning military veterans, who often need to wait months, even years for customized prosthetic limbs made via traditional methods. The Tylers have spent the last two years researching the feasibility of using 3D printers for prosthetics and think that they have functional designs ready to be printed. All they need is a printer large enough to make their them a physical reality.

The Tylers are experts in the field of prosthetic fabrication: both are ABC board certified orthotists and prosthetists and hold Masters of Science in Orthotics and Prosthetics from Georgia Tech. They also regularly travel to Haiti and Belize and help bring prosthetic limbs to populations that typically would be unable to afford them. And, from their rather

Are those prosthetic limbs for ants?! The Tylers need to be able to make them bigger.