Recently, 3D Printing Industry reported on Michigan Tech’s Tolou Shokuhfar

Shah says, “People have tried to print graphene before, but it’s been a mostly polymer composite with graphene making up less than 20 percent of the volume.” She finds that using graphene ink on a smaller scale actually decreases many of the material’s most esteemed properties. Mixing in higher volumes of graphene flakes into the ink results in fragile structures that are difficult to manipulate. Shah’s ink uses sixty to seventy percent graphene, preserving the integrity of the material, including its electrical conductivity. The secret ingredient in Shah’s ink is a mix of biocompatible elastomer and fast evaporating solvents.

Shah explains, “It’s a liquid ink. After the ink is extruded, one of the solvents in the system evaporates right away, causing the structure to solidify nearly instantly. The presence of the other solvents and the interaction with the specific polymer binder chosen also has a significant contribution to its resulting flexibility and properties. Because it holds its shape, we are able to build larger, well-defined objects.”

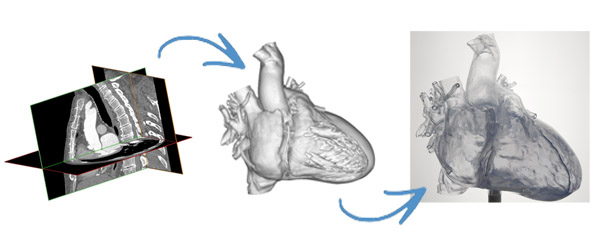

Shah and Jakus’s research is described in a recent paper in the April 2015 issue of ACS Nano, called “Three-Dimensional Printing of High-Content Graphene Scaffolds for Electronic and Biomedical Applications” written by Jakus and another Materials Science and Engineering professor, Mark Hersam. On the cover of the issue, ACS Nano features the team’s 3D printed graphene scaffold, which Shah believes could one day play a significant role in regenerative medicine and tissue engineering (like Michigan Tech’s cartilage and nerve cell research). In fact, her team has already run some tests populating one of the scaffolds with stem cells.

In the experiment, the cells not only survived, but they divided, multiplied, and transformed into neuron-like cells. Shah explains, “That’s without any additional growth factors or signaling that people usually have to use to induce differentiation into neuron-like cells. If we could just use a material without needing to incorporate other more expensive or complex agents, that would be ideal.”

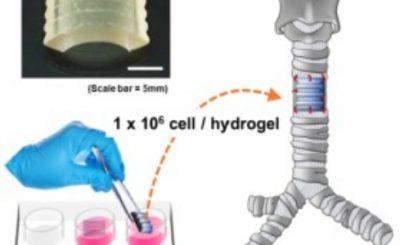

The Northwestern team also points out that the graphene’s electrical conductivity and biocompatible elastomer combination also allows for structures that are flexible and strong enough to be sutured to existing tissues. Shah posits that the material could one day be used for medical implants or biodegradable sensors. “Cells conduct electricity inherently — especially neurons,” she says. “So, if they’re on a substrate that can help conduct that signal, they’re able to communicate over wider distances.”

This particular graphene-based ink is just one of 30 printable bioinks that Shah has formulated with her graduate team. All of these inks are compatible with tissues and organs, and all of them could potentially be used as ground zero for printing more complex organs. Shah says, “There are many different tissue types, so we need many types of inks. We’ve expanded that biomaterial tool box to be able to optimize more mimetic engineered tissue constructs using 3-D printing.”